Concrete Structure Scanning

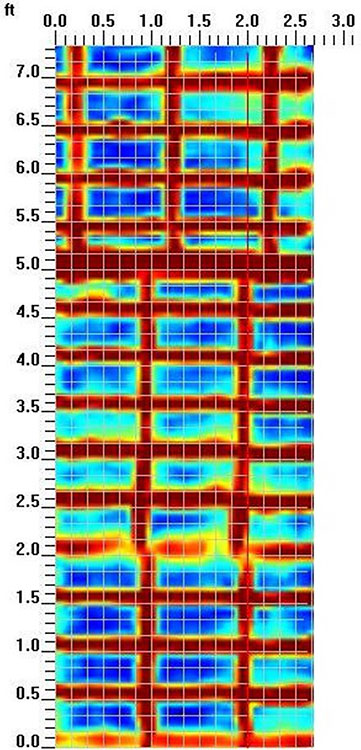

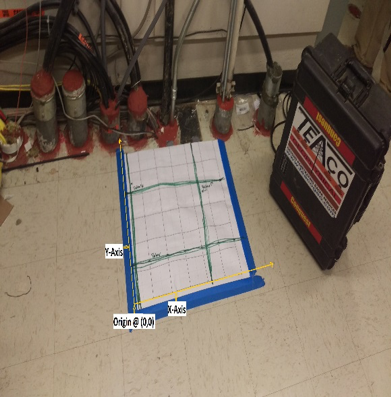

In many instances the need to identify the location of engineered structural components embedded within concrete prior to sawing, coring, or cutting requires that areas be scanned for these items. Traditionally, X-Rays have been used and the associated jobsite delays combined with the possible exposure of workers to ionizing radiation is making this technology obsolete. TeaCo utilizes a high frequency GPR platform specifically designed to meet the concrete industry’s needs that can be operated safely without harm to surrounding workers or the environment.

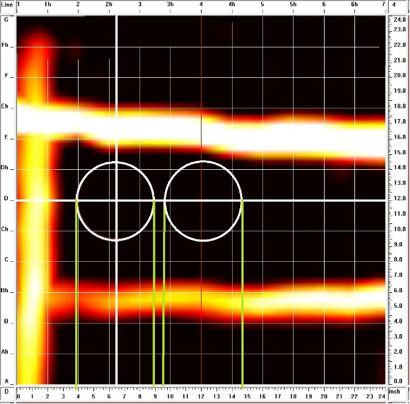

The system is designed to quickly evaluate concrete through non-destructive testing (NDT) methodology while delivering a fast, real-time imaging option for people who need to evaluate, drill, or cut structures on the spot. It can locate rebar, voids, PVC, metallic conduits, locate & estimate the depth of post-tension cables, reinforcing mesh, and transfer that data to a PC for further enhancement.

Comparisons made between conventional x-ray technologies verses this newer GPR technology readily illustrates the added value for project managers to consider:

- There is NO ionizing radiation like X-Rays and eliminates that associated health risk to workers

- Elimination of ionizing radiation removes the need of security personnel to prevent access during exposure(s)

- Concrete structure scanning platform requires access to ONLY one side in order to image, whereas x-ray film is placed on one side and the exposure comes from the other.

- Results are in real time without the delays in the developing process like x-rays.

“Guide Coring to Avoid Embedded Structures”